This is part 3 of "building an audio mixer with effects". For part 1 go here, and for part 2, go here.

The mixer is working fine, and already has got two PT2399 circuits for delay. But now it is time to add some reverb. For reverb I decided to use an FV-1 based design. Experimental Noize has some nice small boards built around this chip, preprogrammed for different purposes. I decided to go for the SKRM-C8-R02 Mono-In/Stereo Out reverb and delay module.

I wanted to use a rotary switch to select between the different programs. The SKRM data sheet proposes to use a 74HC148 8 to 3 Line Priority Encoder for this purpose. Hence, there is a need for a small PCB to mount the SKRM and the 74HC148 (in addition to some additional components). Although I have used KiCad and OSH Park for PCB production previously, I wanted to test Fritzing for this small project.

I drew a quick diagram in Fritzing, swithced to PCB-view and the auto-router took care of the rest (at least most of it).

After a about ten days the card arrived in my mailbox.

The board came out quite nicely. Although I am very satisfied with the result, I do not think I will use Fritzing for my next project. OSH Park and other alternatives are way cheaper, and I think the Fritzing software is a bit limited compared to Eagle or KiCad (and even if the Fritzing-software is very simple to use, Eagle and KiCad are not that difficult to learn). The files are available at the Fritzing-site in case you are interested.

It took about 10 minutes to add the few components :-). It is only a 74HC148, a capacitor and a pull up resistor network.

Then I slammed the SKRM on top of it, soldered the connectors, and started jamming with some heavy reverb. But wait, I forgot one thing, namely to securely mount the PCB inside the mixer. A simple solution is to screw standoffs to the front panel, but the screws would interfere with the front panel design. I could also glue the standoffs to the front panel, but I just hate to glue things together when there is a slight chance that I might want to dismantle it later.

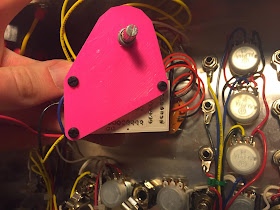

Hence, I created a plate to screw the PCB standoffs to, that is fastened with the rotary switch. It is designed in OpenSCAD and 3D-printed.

The above picture show how it looks like inside the mixer. Notice that the plate (in pink) is fastened together with the rotary switch.

The above picture show how the mixer looks like inside. The SKRM is driven by a LM7805 which is connected to the +12V rail (the blue heatsink can be seen on the bottom part of the picture). The circuit draws about 170mA, even if the data sheet states it should be less than 75mA. The reason? I do not know.

DIYcrap mixer. Now with reverb.

Wednesday, February 25, 2015

Monday, February 2, 2015

Building an enclosure for Mutable Instruments Shruthi-1

About a year ago I ordered a Shruthi-1 PCB and a Four Pole Mission PCB from Mutable instruments. After sourcing the components, it was a quick and enjoyable build. The synth has, however, been sitting in my drawer for a long time waiting for an enclosure.

First, I thought of buying the metal enclosure from Mutable Instruments. Besides the fact that the metal enclosure costs ¢55 (not a bad price, but still), I had, due to financial reasons, used different buttons than those recommended my Mutable Instruments. Since I had no intention to change those, I had to make my own enclosure.

Before bragging about my design I have to inform you that there is an excellent downloadable enclosure out on Thingiverse:284637. I tried it, but I just could not get it to print nice on my small RepRap Huxley.

I used OpenSCAD since it is Open Source and pretty nerdy. The box is pretty simple (and boxy), but takes only a couple of hours to print and consists of only three parts.

I created small cylinders for the LEDs. In this way they are highly visible on the front panel although the PCB is about 10mm below the panel. The cylinders also ensures that there is no light leakage from one LED opening to the next.

The final case looks ok. However, the Shruthi is not the easiest synth to use, at least when none of the buttons are labeled in any way. Therefore, I waned to create a panel with labels on.

Using the command "projection(cut=false)", the 3D drawing of the front panel can be converted to 2D. Then it is possible to export a DXF-file which can be imported in Inkscape. I learned this technique from this blog.

Once imported in Inkscape, I can create some text and stuff on the front panel. I used the same approach as I did on my mixer, and printed the front panel on some piece of colored thick paper.

Before laminating the paper, I cut out the opening for the display with an exacto knife and punched 3mm holes for the LEDs with a drill bit.

This is the final unit. You can download the design files on thingiverse if you like, and hack the heck out of it. The OpenSCAD-file is parametrized and it should be fairly easy to alter the design for whatever buttons you might have.

Here goes some additional pictures.

The front panel is secured with the nuts on the five potmeters.

The back plate is secured with the plastic nuts on the audio jacks.

First, I thought of buying the metal enclosure from Mutable Instruments. Besides the fact that the metal enclosure costs ¢55 (not a bad price, but still), I had, due to financial reasons, used different buttons than those recommended my Mutable Instruments. Since I had no intention to change those, I had to make my own enclosure.

Before bragging about my design I have to inform you that there is an excellent downloadable enclosure out on Thingiverse:284637. I tried it, but I just could not get it to print nice on my small RepRap Huxley.

I used OpenSCAD since it is Open Source and pretty nerdy. The box is pretty simple (and boxy), but takes only a couple of hours to print and consists of only three parts.

I created small cylinders for the LEDs. In this way they are highly visible on the front panel although the PCB is about 10mm below the panel. The cylinders also ensures that there is no light leakage from one LED opening to the next.

The final case looks ok. However, the Shruthi is not the easiest synth to use, at least when none of the buttons are labeled in any way. Therefore, I waned to create a panel with labels on.

Using the command "projection(cut=false)", the 3D drawing of the front panel can be converted to 2D. Then it is possible to export a DXF-file which can be imported in Inkscape. I learned this technique from this blog.

Once imported in Inkscape, I can create some text and stuff on the front panel. I used the same approach as I did on my mixer, and printed the front panel on some piece of colored thick paper.

Before laminating the paper, I cut out the opening for the display with an exacto knife and punched 3mm holes for the LEDs with a drill bit.

I had to extend the buttons with some Sugru to make the hight appropriate for the front panel. Looks a bit strange, but it works surprisingly good.

Here goes some additional pictures.

The front panel is secured with the nuts on the five potmeters.

The back plate is secured with the plastic nuts on the audio jacks.